Introduction

In the era of advanced technological solutions, industries across the globe are constantly seeking ways to enhance their operational efficiency, minimize downtime, and ensure the safety of their processes. One crucial technology that has emerged as a cornerstone in achieving these goals is the Supervisory Control and Data Acquisition (SCADA) system.

Additionally, according to market research experts, the market for industrial control systems, which includes SCADA systems, is expected to grow to $181.6 billion by the year 2024.

1. What is SCADA System And How Does It Work ?

So, what is SCADA? At its core, a SCADA system is a centralized control system that enables monitoring and control industrial processes. The acronym SCADA stands for Supervisory Control and Data Acquisition, emphasizing its dual functionality of overseeing operations and collecting data from remote locations. This system plays a pivotal role in industries where real-time monitoring, control, and data acquisition are critical for efficient and safe operations.

The SCADA software is the backbone of the entire system. It provides a user-friendly interface for SCADA operators to visualize and manage industrial processes. This software is designed to process large amounts of data swiftly, enabling quick decision-making and efficient control of operations.

2. Where is SCADA Used?

The adaptability of SCADA to scenarios requiring remote monitoring, control, and data acquisition has led to its widespread adoption in diverse sectors.

- Energy Sector: SCADA is extensively used in the energy sector for monitoring and controlling power generation and distribution, ensuring efficient and reliable electricity supply.

- Water Treatment Plants: SCADA systems play a crucial role in water treatment facilities, overseeing processes such as water purification, chemical dosing, and pump control to ensure the delivery of clean and safe drinking water.

- Manufacturing Industry: SCADA is employed in manufacturing to monitor and control production processes, optimizing efficiency, minimizing downtime, and enhancing overall production quality.

- Transportation and Traffic Management: SCADA systems are utilized in transportation for real-time monitoring and control of traffic signals, aiding in traffic management, congestion reduction, and improved road safety.

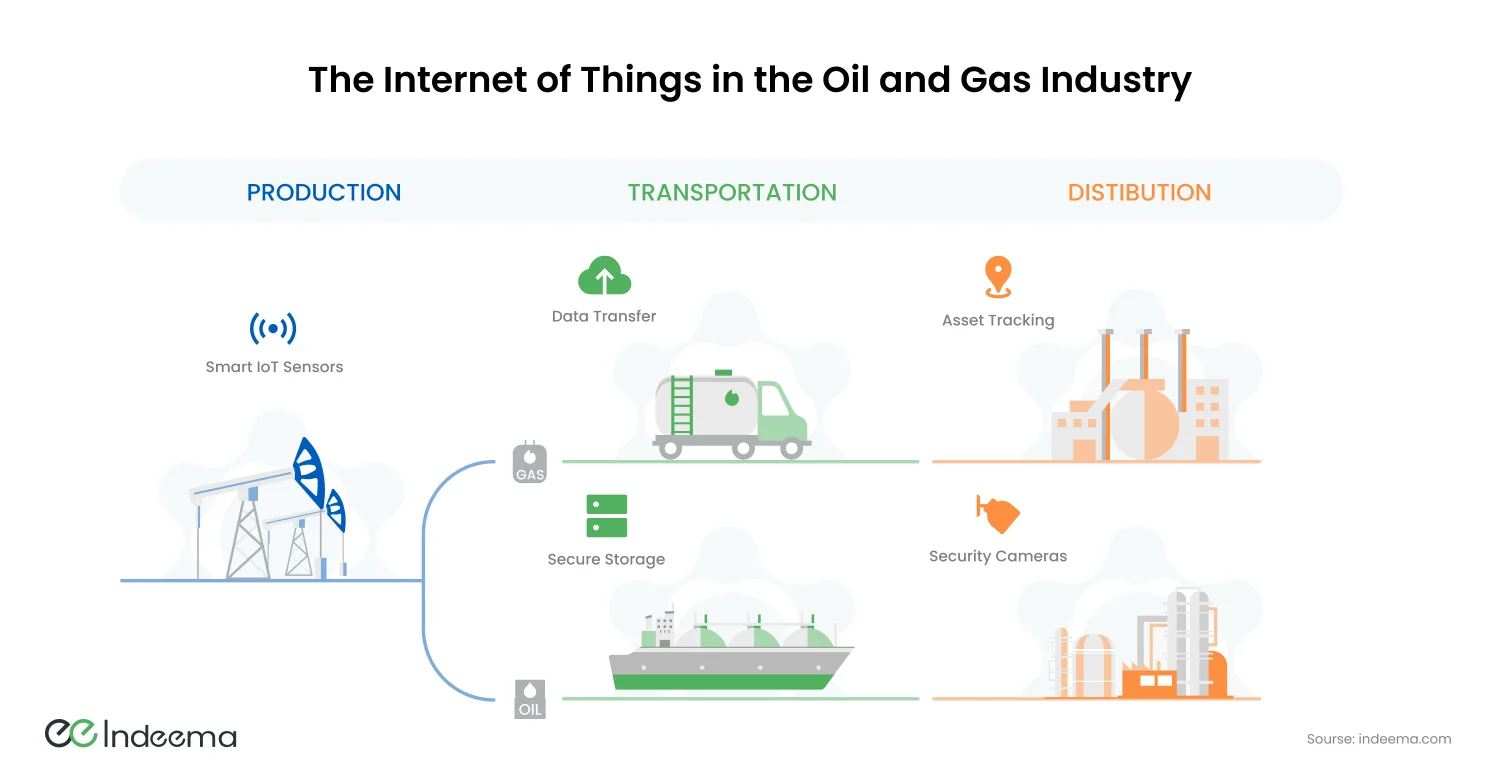

- Oil and Gas Exploration: In the oil and gas industry, SCADA is used to monitor and control remote drilling and extraction operations, ensuring the safety and efficiency of these critical processes.

- Telecommunications: SCADA systems contribute to the telecommunications sector by monitoring and managing network infrastructure, ensuring reliable and uninterrupted communication services.

- Environmental Monitoring: SCADA is applied in environmental monitoring to track pollution levels, air quality, and other environmental parameters, supporting efforts to address environmental challenges.

- Aerospace Industry: SCADA is integrated into the aerospace industry to monitor and control manufacturing processes, ensuring precision and quality in the production of aircraft components.

- Healthcare Facilities: SCADA systems are utilized in healthcare facilities to monitor and control critical infrastructure, including power distribution, HVAC systems, and medical equipment, ensuring uninterrupted healthcare services.

2.1 Types of SCADA Systems

2.1 Types of SCADA Systems

Enterprise SCADA Systems: These are comprehensive solutions designed for large-scale enterprises, offering centralized control and SCADA monitoring capabilities across extensive industrial processes.

Distributed SCADA Systems: Tailored for industrial organizations with geographically dispersed operations, distributed SCADA systems provide decentralized control and monitoring, often with interconnected subsystems.

Web-based SCADA Systems: Utilizing web technologies, these systems offer remote access to SCADA functionalities through web browsers, enabling users to monitor and control processes from any location with internet access.

Mobile SCADA Systems: Designed for mobile devices such as smartphones and tablets, these systems provide on-the-go monitoring and remote control capabilities, enhancing flexibility for operators.

Compact SCADA Systems: Ideal for small to medium-sized businesses, compact SCADA systems offer scaled-down versions of the technology, providing essential monitoring and control features at a more accessible scale.

SCADA as a Service (SaaS): Representing a cloud-based approach, SCADA as a Service allows organizations to access SCADA functionalities through a subscription model, reducing the need for extensive on-premises infrastructure.

PLC-based SCADA Systems: These systems integrate with Programmable Logic Controllers (PLCs) to control and monitor industrial processes, offering a seamless connection between the SCADA software and the field devices.

Communication-based SCADA Systems: Focused on efficient communications protocols, these systems prioritize the exchange of data between the SCADA software and field devices, ensuring real-time monitoring and control.

Open Source SCADA Systems: Embracing open-source principles, these systems offer flexibility and customization options, allowing users to modify and enhance the software based on their specific needs and preferences.

3. SCADA in Action: 10 Key Benefits You Can Expect

Implementing a SCADA system offers a plethora of benefits to industries:

1. Improved Efficiency

SCADA systems optimize processes, leading to increased efficiency and reduced resource wastage. The ability to monitor and control operations in real-time allows for timely adjustments, enhancing overall efficiency.

2. Remote Equipment Monitoring & Control

With SCADA, operators can remotely monitor and control equipment, reducing the need for on-site presence. This capability not only saves time but also enhances safety by minimizing exposure to potentially hazardous environments.

3. Reduce Downtime

The quick detection of issues and prompt response enabled by modern SCADA systems significantly reduces downtime. This results in increased overall productivity and cost savings for industries.

4. Sending Real-Time Data

Networked SCADA systems provide real-time data, empowering decision-makers with accurate information for timely and informed choices. This ensures that actions are taken based on the most up-to-date insights.

5. Improved Safety

Enhanced monitoring and control capabilities contribute to improved safety in industrial settings. SCADA systems can quickly identify anomalies and trigger alarms or automatic shutdowns to prevent accidents.

6. Increase Productivity

By streamlining processes and minimizing downtime, SCADA systems contribute to increased productivity. The ability to make data-driven decisions results in optimized workflows and resource utilization.

7. Flexibility & Scalability

SCADA systems are designed to be flexible and scalable, accommodating the evolving needs of industries. Whether a small-scale operation or a large enterprise, SCADA solutions can be tailored to fit the specific requirements of any organization.

8. Faster Response Time

The real-time monitoring and control capabilities of SCADA lead to faster response times in addressing issues or making adjustments. This agility is crucial for industries where swift actions can prevent costly consequences.

9. Improve Quality

SCADA systems contribute to the improvement of product and process quality by ensuring consistent and controlled operations. This is particularly crucial in industries where product quality is paramount.

10. Data Management - Collection and Analyzing

SCADA systems excel in historical data management, collecting vast amounts of information and providing tools for in-depth analysis. This data-driven approach facilitates strategic decision-making and continuous improvement.

4. Explore SCADA Systems Real Examples

To better grasp the real-world SCADA applications, let's delve into a few monolithic SCADA systems examples of how industries have successfully implemented these systems to enhance their operations and what is SCADA used for.

4.1 Energy Sector

In the energy sector, Pacific Gas and Electric Company (PG&E) relies on SCADA systems to monitor and control its extensive power grid. SCADA enables PG&E to manage electricity distribution efficiently, respond swiftly to faults or outages, and optimize the performance of its power generation infrastructure.

4.2 Water Treatment Plants

The Metropolitan Water District of Southern California employs SCADA systems to oversee water treatment processes. These systems monitor water quality parameters, control chemical dosing, and manage the intricate network of pumps and valves. SCADA ensures the delivery of high-quality drinking water to millions of residents across Southern California.

4.3 Manufacturing Industry

Toyota, a pioneer in lean manufacturing, utilizes SCADA systems as a crucial component of its production processes. SCADA helps monitor the entire manufacturing floor, providing real-time insights into equipment performance, production efficiency, and inventory levels. This contributes to Toyota's renowned production improve efficiency and quality control.

4.4 Transportation and Traffic Management

Florida's SunGuide Central Traffic Management System employs SCADA to monitor and control traffic across major highways. SCADA systems enable real-time monitoring of traffic flow, incident detection, and dynamic adjustment of traffic signals, contributing to improved traffic management and reduced congestion.

4.5 Oil and Gas Exploration

VikingScada is an IoT web application for monitoring the functioning of manufacturing monitoring equipment such as oil, water, and gas. The technique minimizes the quantity of gasoline needed as well as the time required to manually take measurements from each place, hence reducing human error. It also ensures uptime because personnel receive immediate alerts in the event of a problem.

VikingsSCADA tasked Indeema Software with designing a unique IoT solution. This program was designed to monitor and retain data from devices put at end users' locations, especially in the oil, water, and gas industries.

VikingsSCADA tasked Indeema Software with designing a unique IoT solution. This program was designed to monitor and retain data from devices put at end users' locations, especially in the oil, water, and gas industries.

Conclusion

In conclusion, the Supervisory Control and Data Acquisition (SCADA) system stands as a cornerstone in the modern industrial landscape, offering a comprehensive solution for monitoring, control, and data acquisition. Now you know what is a SCADA system and how does it work.

Indeema Software stands as a reliable partner to seamlessly implement SCADA system for your project. With a wealth of expertise in industrial automation and IoT solutions, Indeema offers a comprehensive suite of services to design, develop, and deploy SCADA systems tailored to your specific project requirements.

2.1 Types of SCADA Systems

2.1 Types of SCADA Systems